Humans are fantastic at interpreting the world around us through our five senses. We use two of these to sense the vibrating world around us through sound and touch.

From a high-pitched squeaking door hinge showing it needs oil, to the deep rumble of thunder telling us to seek shelter, we instinctively interpret noise and vibrations to help us navigate the world.

Why don't we listen to railways?

Part of the challenge is that the railway is long, sometimes remote, and often inaccessible. The range of hearing via the human ear or microphones is quite limited and we cannot position staff everywhere, for safety, cost, and practicality reasons. This means, historically, that we have been largely deaf to this potentially rich data source.

Why should we listen to railways?

Interpreting vibrations permeates our everyday lives, entering our everyday language.

“That doesn't sound right” may be heard when a car or home appliances start making unusual noises, which then is often followed by a repair or replacement. So too an experienced listener can hear and feel railway issues, for example, a wheel flat on rolling stock, a loose fishplate bolt in a length of track, a bearing fault in a point machine, or excessive arcing from a vehicle pantograph.

An expert ear can often find issues evolving long before they are found by scheduled measurement or maintenance activities.

How can we listen to railways?

A technique known as Distributed Acoustic Sensing (DAS) is well established securing international borders and monitoring pipelines. The technology allows us to extend the range of vibration detection far beyond the human ear, using fiber optic cables.

The technology uses standard single mode fibere optic cables, often already present as part of signalling or telecoms infrastructure. The fiber optic cable itself becomes the sensing element. Up to 100km of fiber (around 80km of rail route) can be measured by a single sensing unit.

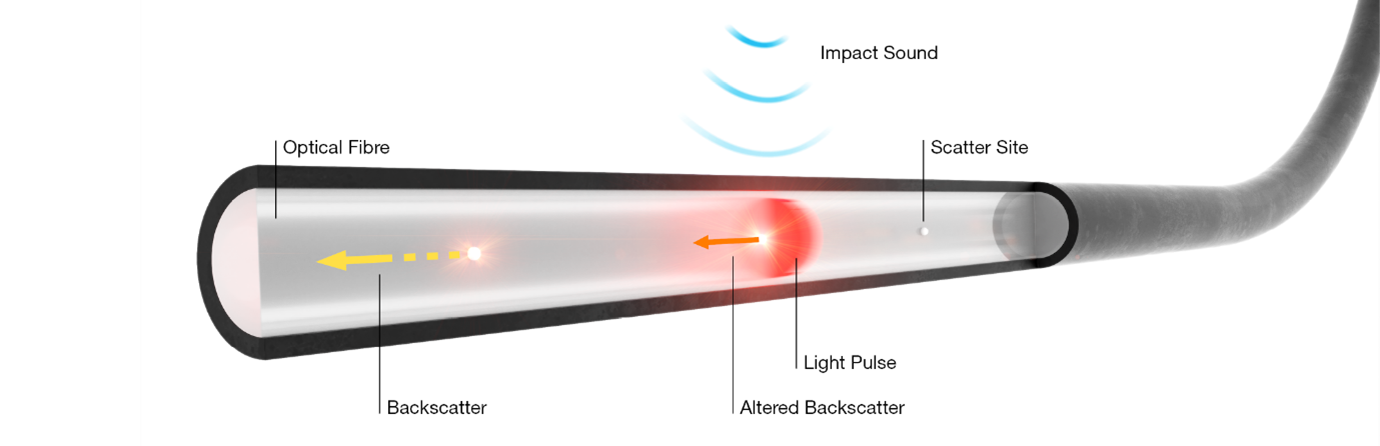

The DAS technique works by using an eye-safe laser in the sensing unit to send light pulses along the fiber. The laser pulses are subjected to various scattering processes along the glass fiber due to their interaction with the glass matrix. A small portion of the laser light is scattered back towards the sensing unit. It is this reflected portion of the light pulse that is measured to derive information. (Figure 1).

The scattering processes within the glass fiber are affected by any strain in the glass fiber such as that caused by its movement or vibration. This phenomenon is known as Rayleigh scattering.

Vibrations of the fibee can be from a passing train, or even the tiny vibrations from footsteps nearby. If the propagation time of the laser pulse is evaluated together with other parameters of the backscattered light, this can be used to find both the location and the frequency and intensity of the vibration of the fibee.

Figure 1 — Schematic of Distributed Acoustic Sensing (DAS).

How Distributed Acoustic Sensing Works

Listening vs understanding

Gathing huge quantities of vibration data from along the entire length of a railway is now possible. However, to make it both useful and usable we must also apply intelligent data analysis.

Was that noise a landslide? Or was it a passing train. Is that someone digging near the track? Or is someone walking along it? Some fiber sensing systems deployed in the rail industry have resulted in excess false alarms. However, by using train tracking experience combined with real railway data and track knowledge, together with machine learning and AI models it is now possible to ‘listen’ to railway assets 24/7 and categorise the events that occur in real time.

Using railway experience together with the latest Al and machine learning provides the ability to turn vast quantities of vibration ‘noise’ into actionable information whilst also minimising false alarms. This delivers a powerful information resource enabling railways to make informed and efficient decisions about safety, operations, and maintenance.

Real railway examples presented in this article only cover a portion of the potential uses that could possibly be realised in the future.

Distributed acoustic sensing

A sensing unit typically segments the fiber into 6.4m sections meaning a 100km fiber run can be considered as an array of over 15,500 vibration sensors distributed along the entire fiber/rail route. Every passing vehicle generates track and ground vibrations allowing infrastructure insight to be gleaned from every train. Other infrastructure events that generate ground vibrations can also be detected, providing continual monitoring combined with comprehensive spatial coverage along the route.

What can vibration reveal about the railway?

There are many established and potential use cases for vibration sensing via fiber optic cable. Here I show four applications that can benefit different teams across the railway. It should be noted that the same infrastructure and sensing technology supports all these applications, potentially at the same time, increasing the value that can be realised from the roll out of a single unified technology to an often already existing asset.

Landslide and Rockfall

A potentially life-saving application of DAS is in the detection of landslides and rockfalls. These natural hazards are an increasing challenge for rail operations teams as extreme weather events become more frequent. When a train meets a large rockfall or landslide, it rarely ends well. Unlike the previous application, here we are monitoring for characteristic ground movements and vibrations along railway routes in real- time. Automated alerts, sent in real-time, allow operations teams to respond to landslides and rockfalls before a natural hazard turns into a railway accident.

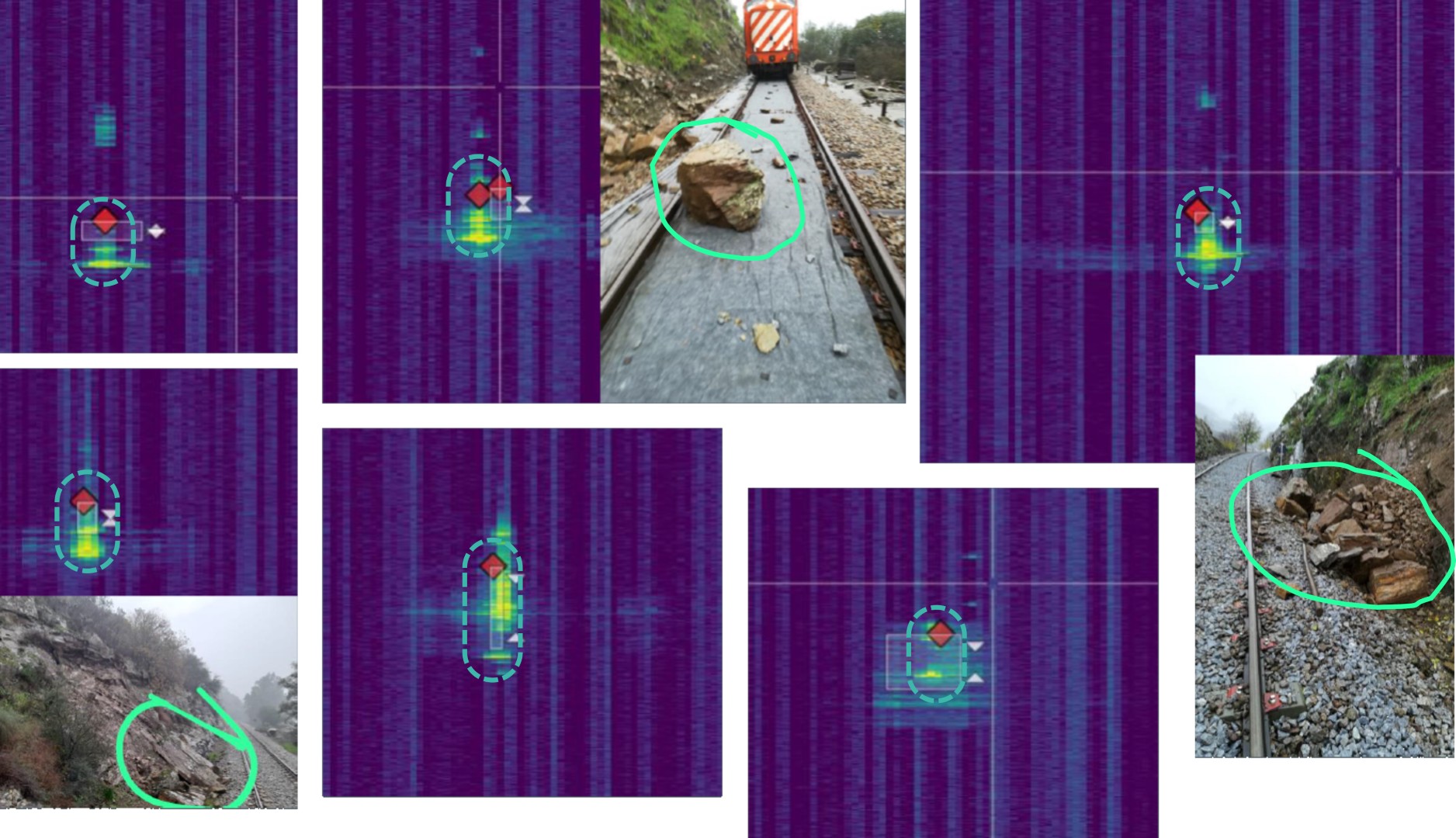

Figure 2. Landslides and rockfalls are potentially life-threatening, but detectable, hazards.

When a landslide or rockfall occurs, ground vibrations are generated by the moving rocks/ground. These vibrations are detected by DAS and watched in real-time by machine learning and Al algorithms. If the characteristic vibrations of a landslide or rockfall are seen, the system generates and sends an urgent alert to the railway operations teams together with a precise location. This enables the operations team to act, avoiding loss of life and damage to infrastructure, rolling stock, and the environment.

To supply the highest levels of accuracy in addition to using algorithms and Al to classify vibration measurements as a potential landslide/rockfall, alerts are verified by the railway operations team, who then initiate the appropriate response. Keeping this ‘human-in-the-loop’ allows detection rates to be further optimised, to exclude ground vibrations triggered by known or planned events such as track maintenance activities, e.g. tamping, or local construction work such as piling.

Alerts generated by this natural hazard monitoring system have already prevented several railway accidents and continue to provide protection for railways in mountainous and challenging environments. Examples of rockfalls and landslides from operational railways together with the vibration data recorded and automated alarms generated are shown in Figure 3.

Figure 3 — Examples of detected rockfalls/landslides, shown together with the automated alarms generated.

Find more on Landslide & Rockfall Detection

Security

Security is a wide-ranging topic meaning different things to different people and four different security applications are highlighted here.

Railways are regarded as critical infrastructure by most governments, and as such their continued reliable operation is vital to many worldwide economies. Threats to operation come in multiple forms including casual or accidental trespass/intrusion, vandalism, petty theft, organised crime, terrorism, and even up to the level of state sponsored sabotage. The railway can be challenging to keep secure due to its long, linear, nature and often isolated or remote assets.

DAS can detect extremely small ground vibrations and is sensitive enough to detect the vibrations from human or indeed animal footsteps. As fiber optic cables are typically laid underground or in ducts/troughs next to the railway track, the covert and comprehensive geographical coverage this delivers enables security information to be gathered across whole rail routes rapidly. This can be particularly important in remote and difficult-to-access areas,

where traditional security measures such as patrols or cameras may be ineffective or impractical.

Security applications can be both reactive — responding to current and evolving situations — as well as being used pro-actively to measure trends, assess the effectiveness of different security strategies, or to gather data to support planning and future budget allocations.

Trespass

The use of DAS for listening for trespass activity along vast lengths of critical infrastructure is already well proven in other industry sectors, such as the oil and gas industry for pipeline protection and the security sector for international border protection. The application of the

technology to the railway brings similar security benefits as well as potential safety improvement applications in cases where teams may be maintaining track in remote areas.

As the fiber optic cables used as the vibration sensing element are typically found underground, they are both covert and difficult if not impossible to avoid.

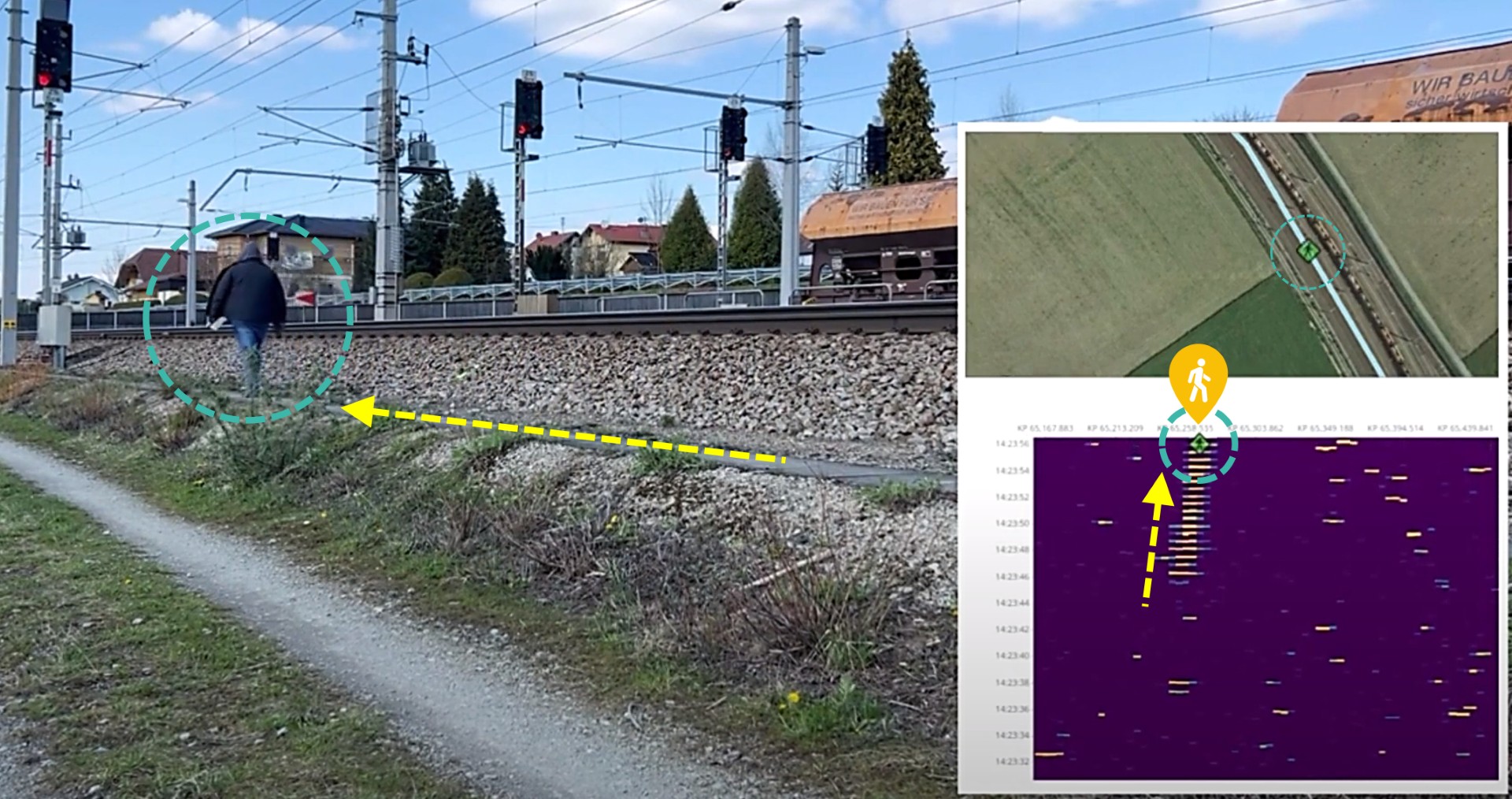

When trespassers’ footsteps are detected, security alerts are generated automatically in real-time. These notifications are sent to the rail operations teams, delivering the alert type together with accurate location information so they can initiate an appropriate response.

Security intrusion data is also recorded and is available historically for analysis to allow improved security planning and to assess the effectiveness of preventative security measures implemented, e.g. fences, patrols or CCTV.

The variety of trespass threat is large, and so risk profiles together with local knowledge can be used to customise the levels of activity needed to generate an alert. Whilst a casual trespasser taking a short cut across the track may typically only endanger their own life, someone accessing the tracks to tamper with or sabotage them is a very real risk. A recent example was when two fiber cables were cut stopping rail traffic across much of Germany, with the effects and delays spanning many international rail services.

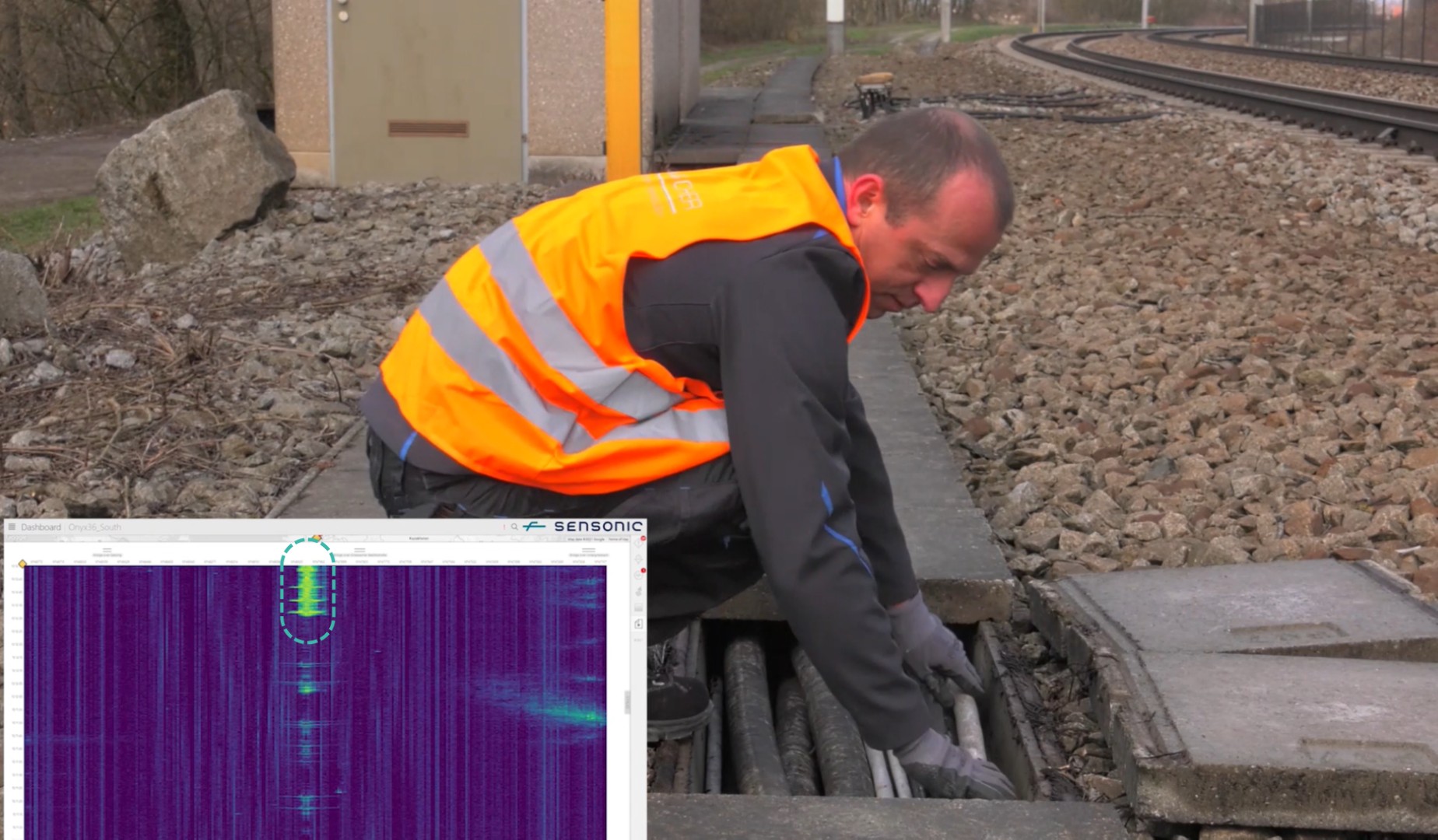

Figure 4 shows a demonstration of the security application in use on an operational railway. The highlighted alarms are automatically triggered when a person is detected walking along the track. An exact geolocation of alarms is available in real-time to the operations teams so they can direct a suitable response. The lower inset graph shows the data that has generated the alarm. On the x-axis is distance along the track. The y-axis shows time with newest data at the top. Bright colours show higher vibration intensity. The individual footsteps and direction of travel are clearly resolvable in the data stream as the trespasser walks alongside the track.

Figure 4 — Video image from security application demonstration. Inset bottom shows the recorded vibration created by the footsteps, and the inset top shows geolocated location.

Digging

Digging activities near or on the rail infrastructure are also a key security concern. Most commonly digging activities are related to theft of cables, but they can endanger rail operations in other ways too, accidentally damaging cables, earthworks, drainage, or other track structures.

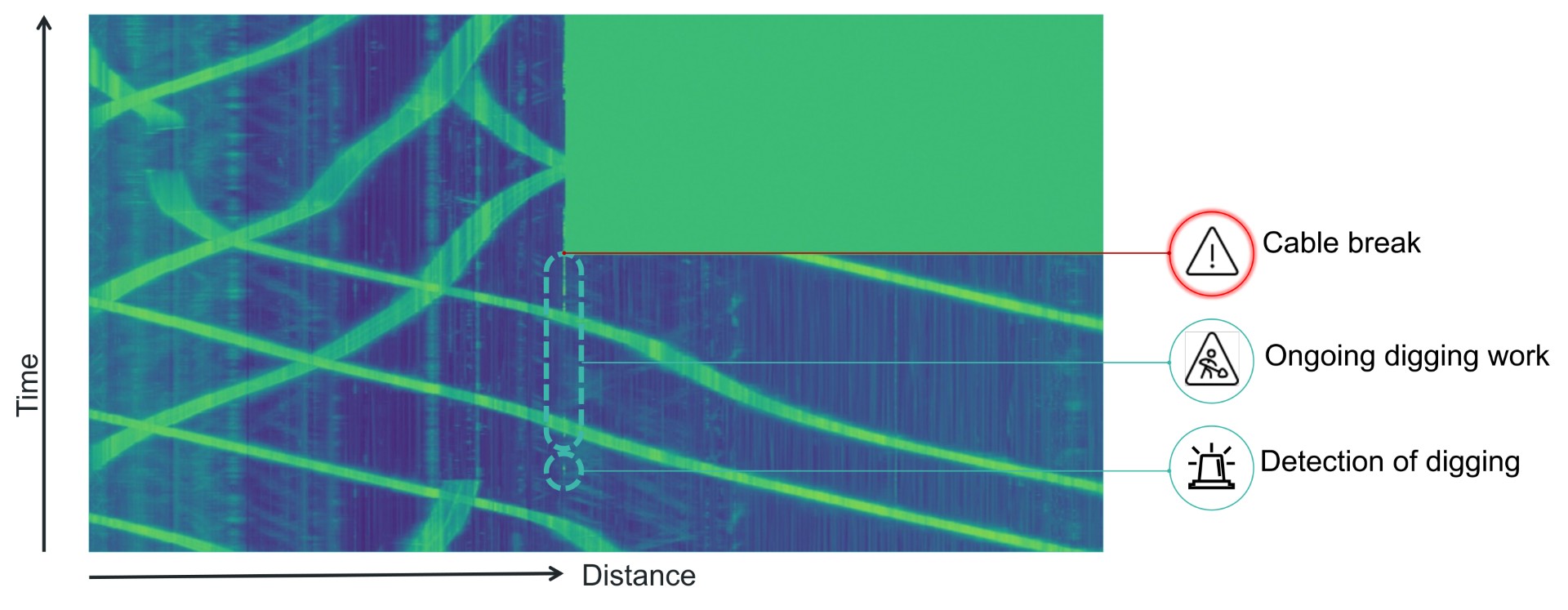

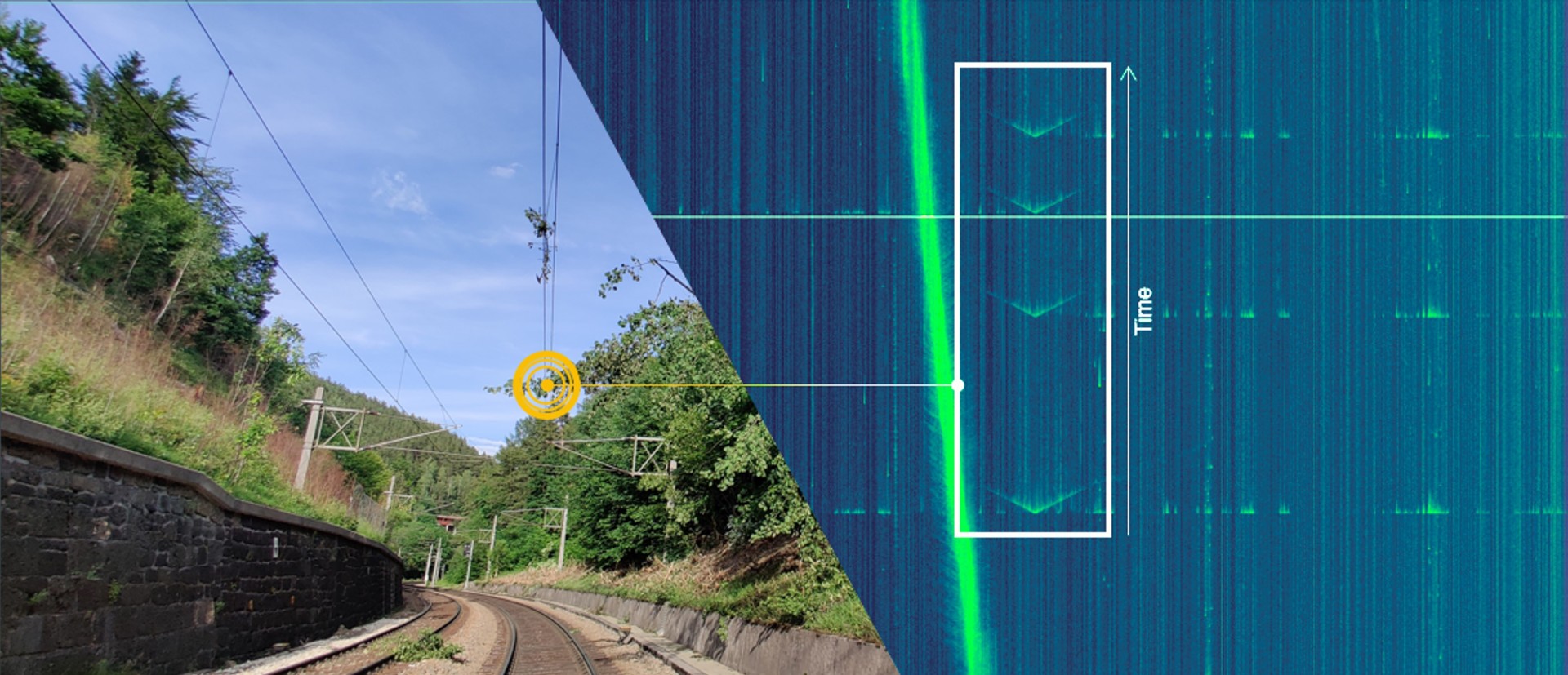

Figure 5 shows data from an operational railway, (the green bands are trains in motion). Digging activity was noted at the highlighted location, continuing for quite some time before the cable was eventually reached and damaged.

Unlike many measuring systems, because the light pulses are introduced and the reflected light is measured at the same end of the fiber optic cable, the system continues to run and record data up until the location that the cable was damaged.

This proves extremely useful for finding the exact location of the cable/digging damage and provides some capabilities during degraded operating conditions. The green part top/right is absent data due to the cable damage.

Figure 5 — Example of digging damage on an operational railway in India.

Cable events

Whilst we have clearly seen where digging has damaged cables in the earlier example. different routes use different cable management techniques, potentially leading to cables being more vulnerable to theft or even tampering. Figure 6 shows a video still from a demonstration, as cables are rouched/moved these generate vibration energy in the monitored fiber optic cable inside the cable trough, which can be clearly seen in the inset graph. This provides the ability to monitor for cable disturbance delivering improved visitiblity of security threats.

Figure 6 — Cable event/tampering demonstration.

Animal intrusion

In an analogous way to detecting trespassers footsteps, the movement of large animals can also be detected and monitored to alert rail operations teams when required. Herds of animals such as cows that may wander on to the track can pose significant risk to rail operations, particularly higher speed passenger services, which can be seriously damaged or even derailed when they are encountered. Large animals such as elephants also pose a significant risk to rail traffic operations in some regions due to their size, as well as the risk of reputational damage from harming iconic and endangered species. In an equivalent way to the trespass example earlier, wandering animals can be detected and alerts issued to local operations staff who can then initiate the appropriate actions.

Find more on Security Applications

Catenary flashover location

Whilst the applications discussed thus far have focused on items interacting directly with the ground generating ground vibrations, significant energy events above the ground, such as an electrical flashover of the overhead catenary, can also induce ground vibrations.

The loud noise of a catenary flashover event is detectable by fiber optic sensing allowing the exact fault location to be quickly determined for inspection and repair.

Overhead electrification sections may be many hundreds of metres in length with hundreds of components to visually inspect for damage following a flashover. The ability to pinpoint the fault location to +/-10m rather than the many hundreds of metres accuracy level of traditional fault indication systems allows accelerated inspections and repairs for incidents with less risk to staff, and a faster recovery of operational status.

Figure 7 — Left, a fallen tree has led to four flashovers of the overhead catenary. Right, the vibration energy accurately identifies the exact location of the fault.

Find more on Flashover Location

Implementation

Fiber optic cables are robust, have a long life, are immune from Electro-Magnetic Compatibility (EMC) issues, and are commonly used in railway signalling and telecoms. They are a known mature technology with both experience and familiarity with trackside implementation in the rail sector. One single unused (dark) fiber in a cable bundle is all that is required to gather vibration data along its length. This means often no new wayside equipment is needed if a spare fiber is already present within a bundle.

A sensing unit can gather data from up to 100km of fiber (~80km of track) meaning there are few if any locations out of reach of this measurement technology. With the ability to turn 100km of fiber into over 15,500 vibration sensors along the railway, rapid coverage of whole route infrastructure information and performance can rapidly be provided.

To complete an installation, all that is needed in addition to the fiber connection is a simple power and internet connection. Once connected to power, internet, and fiber, the ability to gather and start interpreting track vibration data is activated.

As algorithms and Al evolve, the ability to remotely upgrade the detection and monitoring analysis with the latest updates and to expand functionality with new use cases ensures railways can be kept up to date with the latest developments.

This simplicity of roll-out with both rapid installation and scalability allows railways to monitor and protect large lengths of track, entire routes, and potentially complete rail networks without needing to install forests of wayside sensors and supporting equipment.

Conclusion

DAS is a technology which supplies multiple insights to different railway disciplines from the same sensor source. It uses standard fiber optic cables running alongside the operational railway turning them into a series of sensitive vibration sensors. The use of a standard, often pre-existing, fiber optic cable as the sensing element lowers barriers to adoption enabling rapid roll out, as this is both a mature technology and already often an essential part of modern railway infrastructure.

The ability to combine a previously untapped rich data source, together with advanced artificial intelligence and machine learning enables delivery of improved rail infrastructure information.

Improved infrastructure insights are an enabler of improved safety and efficiency gains for the railway.

The railway applications discussed include:

- Landslide and rockfall alerts.

- Security alerts for: Trespass, digging, cable events and animal intrusion.

- Catenary flashover location.

The use of distributed acoustic sensing allows multiple disciplines of the railway to listen intelligently to their infrastructure assets, enabling them to make better decisions.

This article is an extract of one published in IRSE News Issue 310.

Like this article? Share it via the button at the top

Want to know more then hit the button below to message our team.